For several years I've had a new transceiver in my annual plan. This year was no different. What is different this year is that I finally did it. The spur was the upcoming CQ WW SSB contest. Since this will be the first multi-op contest from my station, I was uncomfortable asking others to put up with the relatively ancient Yaesu FT950. It was only marginally acceptable when it was just me using it, and then only during contests when I operated SO2R.

The FT950 is not that bad of a rig, for its time. It is unsuitable for a modern contest station where I want ultimate performance. I've had it for years and it did what I asked of it, and it is now set aside. For the time being it will be a backup rig. It will eventually be sold. Due to the march of technology, perfectly good rigs of an earlier generation fetch increasingly lower resale prices. It is almost not worth selling.

The IC7610 is a complex rig and there is much to learn. I have to learn quickly because the contest is almost here. I moved slowly while setting it up and integrating it into the station to avoid mistakes. For now it is a drop in substite for the second operating position. When the contest is behind me it will be become the rig for the main station. The Yaesu FTdx5000MP will be demoted to the second operating position. It has been my primary rig for more than 6 years, but it's time for it to be set aside.

As I said, it's an expensive item and I did not spend the money without due consideration. Is it worth the money? Many hams would never spend that much on a transceiver; I know that I am reluctant to do so. Needs and means are different for each of us, and for me this was the right choice.

Here's how it looks in the shack, as it has been rearranged for two-position multi-op in CQ WW.

It's small and light, and hardly looks as if it is worth the price. The FTdx5000MP is nearly 3× its weight. When the contest is behind me, I will get deeper into its features and capability. For the next few days I am solely focussed on the features needed during the contest. I am likely to have more to say about the 7610 in the future.

The following is a quick take based on my first impressions. Bear in mind that first impressions can be wrong. Do not interpret this article as a review because it isn't.

Buttons

The FTdx5000 has almost every operator feature on the front panel. The panel is large, the buttons many, and the buttons are small. It has to be this way because the features are many and the text-based menu system is slow and difficult to navigate. This high end rig predates the adoption of touch screens. It is one of the last of the "big iron" transceivers.

Buttons have their good and bad points. The majority of the features are not used or rarely used. That's a waste of panel real estate. They are small and hard to read, especially in dim lighting. You remember the buttons you regularly use and mostly ignore the others. Another point that is rarely considered is that cleaning the multitude of tiny buttons and knobs with their textured rubbery surfaces is difficult. But it must be done. A years long buildup of dirt, grime and skin oil is a subject best avoided in polite company.

The OLED displays age poorly and, as you can see, the ones on the lower right are in dire need of replacement. This is a well known flaw of the '5000. Their replacement will be a winter project.

Another problem with many closely space buttons and knobs is that it's easy to grab the wrong one while you're operating. Often you will accidentally bump the ones nearby with unpredictable results. If it's a feature you rarely use it can take some time to figure out what happened and to correct it.

There are few buttons on the IC7610 front panel. A large fraction of the space is taken by a touchscreen where many features can be directly accessed or accessed via the menus. Whether the physical buttons are assigned to the right features is debatable. Operators will have different opinions depending on their individual needs and interests. It's too soon to have developed a solid opinion of my own.

Menu maze

The number of transceiver features increases with every generation of technology. Buttons and knobs for all of them is impractical. Of course there are many rigs that are designed to have a small feature set and don't need more than a few buttons and knobs. But those are usually smaller or special purpose products that take a minimalist approach for specific purposes such as portable operation. High end rigs are feature rich and need menus.

Although they many be necessary, menus are not always better than buttons. For a sophisticated rig like the IC7610 the menu system is a deep tree with many branches. It can be difficult to reach many features or even to know where to look in the menu system.

The names of novel features can be so unfamiliar that you can easily pass by the one you want. Reading manuals is tedious, and there are two of them for the IC7610, the basic and the advanced. Both are large and from my reading the descriptions are occasionally puzzling or incomplete.

That said, the menu system for the IC7610 isn't that bad considering its extensive feature set. Pressing the Multi key (upper right) displays a context sensitive list of only a few features. For example, transmitter power and mic gain. There are several context sensitive features on the left side of the touchscreen that can be directly accessed by a short or long press.

It took me several days to become reasonably comfortable with the menu system. Every modern rig has a learning curve and each manufacturer has their own ideas for menu design. There are many critics of the FTdx101's menu system. I tried it for myself in Dayton last year. That is one reason I favoured Icom for this purchase.

Menus are a necessary modern evil, so I live with it. I escape a lot of the tedium of operating feature use, like with RIT and XIT, using the keyboard commands of N1MM+. I preferentially do that whether or not I'm in a contest. There's less to learn because the N1MM+ keyboard shortcuts for common features are the same for most every rig.

Connector standards

The simplest things can cause a lot of grief. The most basic interconnection needs are the microphone, headphones, keyer and PTT (in and out). At least headphone and keyer jacks are almost always ¼" or 3.5 mm. I'd prefer they all were 3.5 mm but I can deal with it using the adaptors I've accumulated over the years.

But...microphones? Dynamic vs. electret, 3.5 mm vs 8-pin Foster, and different pin outs for the same physical connector. This must be quite the revenue generator going by the extortionate prices they charge for their branded lines of microphones, complete with their unique mic connectors and features. One of my first jobs was to make an adaptor for the 8-pin Foster connector to allow connection of a 3.5 mm electret mic almost universally used for PC headsets. A USB headset connector would be even better. The connectors are right there on the 7610 just above the mic connector.

PTT was easier in one respect. Unlike so many transceivers, the PTT line (that they call Send for some reason or other -- see my thoughts further below) is a simple phono connector. I have loads of phono-to-phono cables. However, there is nothing simple about connecting a foot switch and keyer for PTT control (that they confusingly also call Send). There's an 8-pin DIN (ACC1) where that resides.

The rig does not include the DIN connector. In fact, the only connector they include with a multi-thousand dollar piece of equipment is a ¼" stereo plug. Typical of most transceivers, the interconnecting cables are included with the other equipment that they sell. In most cases it's their amplifiers.

By some miracle I found one of these connectors lying at the bottom of a box full of orphan connectors and cables that I've accumulated over the decades. I soldered on a phone jack and plugged a splitter into that. I could finally connect the foot switch and keyer.USB

The USB connection to the PC removes clutter from the back of the rig. One cable replaces several. Since it provides both CAT and a sound card, there are no separate audio cables.

There is a prescribed installation process to properly install the driver so that Windows doesn't substitute its preferred driver with which the interface will not work. I appear to have done it correctly since everything works as it should.

One way in which Icom is deficient in comparison to other manufacturers is that not every function on the rig is accessible or completely controllable by the PC. I knew this in advance. There are a few peculiarities when using N1MM+ despite the development team's best effort to overcome those deficiencies. I can live with it.

One day soon I hope we can eliminate the cables entirely when the PC connection evolves to wireless and TCP/IP. Some rigs have already done so and I expect the rest to eventually follow. But for now this style of PC interface is good enough.

It's different

Equipment manufacturers have most of the same features as all the others in the same price class. Of course they also have unique features, and those can be very useful. Competition is good! What annoys me is that for the common features they too often use unique terminology and methods to manipulate those features. This has proved to be an obstacle since I've never owned an Icom HF rig before. I had to figure out their names for the features that I am familiar with.

For example, what most hams call RIT and XIT is called the Clarifier by Yaesu. Icom uses the more common terms so this was easy and welcome. The Twin PBT feature of the 7610 is very nice, but only once I figured out the relationship between the high/low cutoffs, filter selection and width controls and their relationship to the CW pitch control. Okay, maybe that isn't too difficult a difference.

There is a prominent button above the VFO knob labelled Change. Change what? So I pressed it and discovered it's what most other rigs call the A⟺B feature to swap the contents of the two VFOs. I'm still trying to figure out what the XFC button symbolizes but I did finally figure out what it's used for. The bizarre name does not make it intuitive. I'm still puzzling out split and dual watch which we need for 40 meters in the contest.

I was surprised to find that the AF Gain also controls the volume of the CW side tone monitor. That's very odd. It was disconcerting when I first encountered it when, after turning down the gain, I had difficulty hearing what I was sending when I next transmitted.

Speaking of CW, why can't there be a common usage for normal and reverse CW reception? CW (normal) on this rig is the opposite of what I expect (USB reception), and was pretty well the standard decades ago when tubes ruled the airwaves. At least I could reverse the default behavior of CW and CW-R deep within the menu maze.

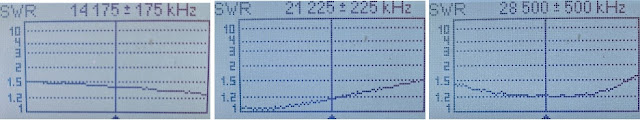

One thing I really liked was the speed of the ATU. Compared to previous rigs I've owned or used it's wonderful. Not only that, the tuner setting hold over 100 kHz. This is far better than the 10 kHz typical of so many other rigs. Unless you use a small magnetic loop antenna there is no need to tune every few kilohertz.

Well, there's lots more I won't bore readers with. You get the idea. Like connectors, I wish rig manufacturers would standardize more of their terminology for common features. They have no particular incentive to do so since their customers don't base their purchasing decisions on it.

Contest priority

I am trying to understand this rig in time for CQ WW SSB this weekend. When the team arrives I have to be able to explain to them how the rig works. I'm getting closer so we'll have to see how it goes.

After the contest I'll have a better understanding. Expect to hear more about the rig and other contest matters after the weekend is in the rear view mirror. When there's a long enough break between contests and DXpeditions I'll swap the IC7610 and FTdx5000MP to make the former my main rig.