This is not a typical product review. Indeed, it is really not a review at all. But as I inspected, cleaned, reassembled and installed the Bencher Skyhawk tri-band yagi I recently purchased secondhand I thought that it might be instructive to look at how an antenna ages and how it is designed. Nothing lasts forever, and problems crop up in the best antennas. They are totally exposed high up on a tower and endure everything nature can throw at them.

Mine is an approximately 12-year old Bencher Skyhawk, a product which has since been transferred to DX Engineering. The new owners have made only a few small changes so that the antenna you can buy today is substantially the same as the original. My observations are mostly applicable to both.

The electrical and mechanical design of this no-trap tri-bander is very good and reviews are almost all very positive. This is a fine antenna. That's why I bought it. But a 12-year old antenna is not a new antenna and time has taken its toll. That's one good reason you don't pay new prices for old merchandise. The resale prices of many products fall precipitously because they age poorly.

The Skyhawk is now on the air at VE3VN. Raising of the antenna was described in a previous article.

This article contains my notes and observations. As already said, this is not a review but a collection of my impressions from inspecting, assembling and raising the antenna. It was an interesting study.

Electrical design

A multi-band yagi is very difficult to design and optimize. This is true with or without traps. All the elements interact, so that even non-resonant elements, and even the tips beyond the traps, have induced current and their fields add to those of the resonant elements. There are no analytical solutions except in the most trivial of cases.

An iterative numerical process is needed to solve the design problem. Before computer modelling, trap yagis had to be refined with great time and expense on a test range. Many manufacturers didn't even bother trying. I've done manual iterations using EZNEC to optimize small yagis but large ones like the Skyhawk require automated algorithms. For my own antennas, I most often take an already optimized design, whether one band or more, which I may tweak to meet my personal performance objectives.

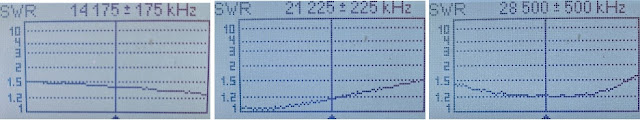

Measurement notes: The SWR plots were made with a RigExpert AA54 in the shack, through

about 40 meters of low-loss coax (except 2.5 m of RG213) and a 2×8

antenna switch. I checked the SWR at the feed point after it was raised but the measured impedance is affected by body proximity. The effect increases with frequency: little change on 20 but noticable on 10 meters.

The Skyhawk is optimized and it is a good design. Although I have not developed a computer model of the antenna, nor have I read an engineering review of it, it appears from its behaviour that some gain may have been sacrificed in favour of an excellent match across all three bands.

There's nothing wrong with that and it may be better for the majority. I tend to favour a little more gain. But that's a nitpick.

12 years of wear

Nothing lasts forever, and that includes antennas. Exposure to the elements takes its toll no matter how good the antenna's mechanical design. An inspection found problems, both small and large. These were corrected before it was reassembled and raised.

- Rivets

- Driven element spacer

- Grease

I laid out the pieces of the antenna on the deck to do the inspection and element assembly. Rivets had to be removed from several elements to break into sections that would fit on the truck.

It was an excellent opportunity to inspect how rivets perform over time. I was interested because I've never owned a yagi that used rivets and I didn't use them on my many home brew antennas.

Rivets

Rivets have always struck me as inadequate for joining the sections of tapered element since they are quite small. I wondered if they were strong enough to last and whether the longitudinal stress on the element would accelerate failure of the softer aluminum alloy tubes. Disassembly of the antenna for transport gave me an opportunity to inspect their long term behaviour.

On the left is an improperly seated rivet head. I drilled out several of these to inspect the holes and insert new rivets. There was no obvious damage to the tubes or rivets in most cases so the protruding heads were likely due to mishandling of the rivet tool. The heads of all the rivets protrude around most of their circumference since it's flat and the tube is cylindrical. That isn't ideal but it seems to work.

On the upper right is a damaged hole where rivets were drilled out to disassemble the element. The sides of the hole are clean so it is possible that it was due to careless application of the drill. I left it as is and inserted a new rivet. The resulting bond was good since the rivet head is larger than the hole in the outer tube and the inner tube wasn't damaged.

Close inspection of the inner tube of one telescoping joint was enlightening. The hole is longitudinally elongated and the inside hole rim is roughly bevelled. The elongation is slight, probably no more than 0.020", and it is sometimes less (my calipers didn't fit very well for accuracy). This is what I expected since mechanical stress on the element is primarily longitudinal.

The ⅛" diameter of the stainless rivets is a small, hard surface that can amplify the stress and push the softer aluminum aside. However, it isn't enough to be of concern so I inserted new rivets and continued.

The outer diameter (OD) of the smaller telescoping tube is less than the larger tube's inner diameter (ID). In both cases the wall thickness is 0.058", which is the most common US made aerospace alloy tubes used for telescoping yagi elements in ⅛" steps. For a press fit the wall would have to be 0.0625". That leaves a maximum gap of 0.009" when the tubes touch on one side. The tubes thus slide together very easily. Please note that the gap is less than it appears in the pic due to shadowing.

The antenna obviously works well despite the gap, although it bothers me a little. A press fit a poor choice for antennas since if you could insert the smaller tube it'll probably never come out again! Oxidation, stress and galling take their toll. For full circumference contact the outer tube must be slit and a gear clamp used to squeeze them together. That introduces two points of failure: the slit and the clamp. High quality stainless clamps are essential for reliability.

There are other ways of bonding telescoping tubes. A few of those which are applicable to element tubes were described in the blog when I was building my many yagis. Each method has its pros and cons, including rivets. Perhaps rivets aren't so bad after all.

There are many online resources that explain rivets and how they work, and how to use them. High tensile strength stainless rivets are inexpensive and widely available. It's well worth wasting a few to practice using the rivet tool. I drilled a few ⅛" holes in scrap aluminum and practiced until I was sure of what I was doing. The rivet tool came with the antenna.

It takes a lot of force to seat the rivet and break the narrow neck. I found it easiest to place the element and tool on a solid surface and press the upper handle with one hand while using my other hand to align the tool head with the tubes and to ensure contact between the rivet head and the tool tip. Inset is a closeup of properly seated rivets that were drilled out. You can see how the rivet bulb expands the shank upward to squeeze the tubes together against the rivet head.

All conductive joints in a yagi should be coated to prevent oxidation, prevent binding of telescoped tubes and assure conduction. Many hams skip this step and they should not. I've taken apart many "dry" antennas that required restoration. Some use dielectric grease, and it can work well if it doesn't dry out. A better choice is a conductive grease, which is essentially dielectric grease with a suspension of microscopic metal particles.

The manual states that the Bencher product was shipped with a product called Butter-It's-Not. The name is familiar but I've never seen it and I had difficulty searching for it online -- searches favour links to margarine sites! In any case there are many products. Whatever was used on my Skyhawk, all the grease had dried, leaving a residue of the suspended metal and whatever else. From the residue at least two different products were used.

I lightly sanded the exposed joints to renew them and greased them. Rivetted joints were left as is. The product I use is Noalox. I've had good success with it. The joints remain slippery after many years. I know there are better products that I have less experience with so don't take this as a firm recommendation. My squeeze bottle is so old that the plastic is cracked and repaired with clear packing tape. I've greases joints in countless antennas over the years. A small amount goes a long way. It's cheap insurance so don't skimp.

Driven element spacer

Feeding multiple elements directly from a common feed point puts them in close proximity. Without one or more spacers along their lengths the driven elements would strike one another when the wind is more than a light breeze. That would be catastrophic since the transmitter would fault due to SWR when they make contact.

The Skyhawk uses one spacer on each side of the boom to hold the three driven elements. Only the 15 and 20 meter elements are at risk of touching, and that's very unlikely unless the tubes are severely stressed. If wind or ice of such severity were to occur, you'd likely have bigger worries!

A common complaint in many online review of the antenna is that over time the bundle of driven elements develops an S curve. The reason is that the spacer gradually slides sideways on the 10 and 15 meter driven elements while waving in the wind. When it slides it tends to stay in its new position because the tube fit is tight. Only on the 20 meter element is the spacer trapped so that it can't move.

The plastic spacer is very tough but not indestructible. Apart from the unsightliness of twisted elements, the spacer and tubes are placed under increased stress. You can see where one of the spacers cracked, not surprisingly on the 20 meter element where the hole in the spacer is largest. I'm surprised that this product flaw has not been resolved.

My solution was to fix the spacer position on the 10 and 15 meter elements. A combination of small hose clamps and UV-resistant cable ties are lightweight and get the job done. It takes very little resistance to prevent the spacer from creeping.

I ventured to repair the cracked spacer rather than order a replacement. I drilled a hole and threaded a heavy duty cable tie through it. The tie braces against the element to bind the sides of the crack.

When kept in the correct position, the radial stress ought to be low. The plastic itself is quite tough (it survived the crack). Time will tell whether my repair is effective.

Element-to-Boom clamps

The element-to-boom clamps have no way to fix the element centre to coincide with the boom. All the elements are insulated from the boom with bonded plastic sleeves and you simply judge by eye (or a ruler) as you tighten the clamp bolts. Perfect centering is irrelevant to performance but I do it anyway.

The driven element clamp alignment is more critical (picture is from the DXE manual). These three elements are split for feeding. Rather than one long plastic sleeve, there's a short one on each side of centre. The straps for feeding the elements in parallel are wide and carelessness can cause a short between the strap and the element clamp (which contacts the boom). I made sure the clamps were properly tightened to prevent the elements from creeping due to wind stress.

I wish the design of the feed and clamps were better. However, I haven't heard any complaints on various fora of shorts developing over time. It must happen but perhaps it's rare. A raised lip or rim on the inner side of the sleeve would reduce the risk.

Another peculiarity (or benefit) of the clamp design is that there is no way to position or align the elements along the boom. There is a bolt that run through the upper half of the clamp and the boom. In a few cases the bolt does double duty to bond the boom sections and the boom compensator.

Alignment was excellent except for the driven elements. They are less than 2° askew. It isn't noticable except when you sight along the boom. The PVC element compensator doesn't age well so it is no longer straight. That isn't the fault of the clamp, and it doesn't matter.

Boom attachments

The antenna has no boom truss despite its 24' length and with the longest (heaviest) 20 meter elements mounted at each end. Despite that lack the boom is pretty hefty and sags very little. You can get an idea from the view along the boom towards the reflector end.

You really don't notice it from the ground. Aside from aesthetics there is a question of how much severe weather load the boom and mast clamp can tolerate without the truss. The antenna is engineered for high winds and some ice so I am not especially concerned. But I do wonder how it'll fare in our harsh winters and occasional severe ice storms. On the other hand, elimination of the truss keeps the mast free of obstructions.

When I removed the antenna from its previous owner's tower I was unfamiliar with the design of the mast clamp. I automatically loosened the saddle clamps and sent the antenna into the hands of the ground crew below. The u-bolts don't pierce the saddles so it isn't difficult to drop the loose saddles.

I later came to understand the two-part design. The mast side of the assembly can be left on the mast for both raising and lowering. The upper nuts on the boom side of the clamp fit into the keyholes of the mast plate and drop into the slots below. When that's done the antenna is secure. The lower nuts can be threaded on and all 4 bolts tightened. The reverse procedure is performed for removal of the yagi.

Keyhole mounts are found on all types of hardware, but this is the first time I've seen it on a yagi. I like it.

When we raised the antenna onto my tower, the mast clamp was already installed and all I had to do was direct the nuts into the slots and have the crew lower the antenna an inch. There was no fussing with multiple saddle clamps (often with short u-bolt legs that require near perfect alignment) to secure the load.

Balun and coax

The balun supplied by Bencher is more compact than the one included by DX Engineering. It appears to have weathered well. I can't say how well the PVC electrical box for DX Engineering's common mode choke will survive other than to note my poor experience with the same enclosure used by Balun Designs.

The balun fits snugly under the boom using special brackets to keep it centred and with adequate space for fitting and weather proofing the coax. I tested it with a dummy load on the workbench and it tested fine, with inductive reactance gradually increasing with frequency due to the pigtails. I do not have a fixture for testing common mode rejection. The quantity and type of ferrite beads determine its performance.

The location of the feed point is not convenient for attaching the coax and rotation loop. The Skyhawk includes a boom bracket to support the coax and thus reduce stress on the connector and balun. Unfortunately, that puts the coax even further out. It isn't very far but you must be comfortable leaning out from the tower to do the work.

Since the feed system is below the boom the coax is routed above the boom. The rotation loop is located on the opposite side of the mast and paired with coax dropping down from the 6 meter yagi at the top of the mast. It is possible to put the rotation loop on the same side of the mast by routing it down on the outside of the driven elements, except that the coax has to be kept rigid as it passes the balun to avoid jostling during rotation. A few more feet of coax makes a cleaner rotation loop on the far side of the mast, so that's what I did.

Tube caps

The antenna comes equipped with plastic caps for the boom and element tips. Only a few of the elements had caps on my Skyhawk. I prefer no element caps so that water can freely flow out should any get in.

I have the boom caps and I put them on. Insects are a greater risk in booms since they are large. It's a trade off. Depending on local conditions it maybe sensible to cap all of the tube ends, or none of them.

So far...

I'm happy with the Skyhawk. The first contact was with VK9LAA and I have made many other DX contacts since, including several of the current DXpeditions. It's easier and quicker to turn this antenna than the prop pitch driven big yagis. Although it is not my best antenna on the high bands, it is usually sufficient to make the contact. The agility it brings to my contesting is very welcom.

For most hams it would be a fine antenna on its own. Just make sure the tower and rotator are up to the job. There are many elements and that adds up to a high wind and ice load.

Another consideration is the price. There are few antennas I would buy new and this one is no exception. Material prices have skyrocketed over the past few years and that makes up a substantial portion of the manufacturing cost. The Skyhawk is not out of line with the prices of similar antennas. I don't see many available on the used market. I buy my antennas used or I build my own, with infrequent exceptions.

Direct comparison with the TH6 hasn't yet been done since their gains will be close and the confounding factors many. 1 to 2 db of difference is difficult to reliably discern by ear or S-meter on receive. On transmit it's a different matter: the extra gain of a no-trap design will be noticed. This is often also true when comparing my stacks to smaller yagis. The contest pile ups are deeper and they last longer.

Most hams are fortunate to have one yagi for the HF bands, and two is uncommon. Easy comparisons are impossible. Hence the reliance by some hams on myth and lore, unreliable opinions and advertising. We do have a tendency to convince ourselves that whatever choice we make is the best choice because it is our choice. Physics begs to disagree.

No comments:

Post a Comment

All comments are moderated, and should appear within one day of submission.