I have a phobia about relays and I really don't understand why. In this age of solid state switching there is something messy or unwholesome about having electro-mechanical devices scattered throughout my station.

Is my attitude entirely counter to the evidence or is there anything to support my fears?

It is good that relays are as reliable as they are since they are everywhere in a modern ham station, more than you might realize. Yet they can and do fail. This is mostly due to two factors: quality and abuse. A little knowledge can help us to get the most from relays. Technology has not advanced so far that relays can be avoided.

As you might guess from my irrational phobia, I am not an expert on relays. I had to learn more about them to assuage my concerns and to choose and use relays in my many home brew projects.

They are used in my station to switch:

- DC and AC power

- Antennas

- Antenna switches

- Antenna direction and stack controls

- Matching networks

- SO2R audio and keyer

Many of those are home brew projects. I even have relays that control other relays! Relays are common in commercial equipment to control power, route transmit/receive RF, inter-stage switching, ATU, BPF, antenna ports and more. One malfunctioning relay can ruin your day or contest.

It's that critical role they play and the risk of failure that stokes my fears. I trust that relays are appropriately selected and employed in commercial equipment. This is not necessarily the case. One famous example is the Yaesu FT102. Every relay in that transceiver had a short lifetime and is responsible for far too many of these otherwise excellent rigs ending on the trash heap.

Mine eventually landed on a flea market table. It sold for a low price that was, unfortunately, fair value. I could have salvaged the rig with replacement relays, which are available, but I deemed it not worth the trouble. It was a great rig in its day but no more.

Returning to my phobia, my lack of knowledge and therefore trust of relays leads to odd behaviour. For example, I have an irresistible urge to idle all the relays in my extensive antenna system when I step away from the shack for more than a few minutes. I don't yet have such a feature in my station automation software so I have move the rig to 6 meters to idle the 2×8 antenna switch and manually deselect directions and modes for the stacks and several other antennas.

Is this a feature I should build for my station automation system? Do relays deteriorate when they're energized? Is it better to leave them energized to avoid turning them off and then on again when I return to the shack? Relays do have lifetimes based on these metrics and many others as well. Let's see what the data can tell us.

Above is an extract from an Omron G2RL datasheet -- you may have to click on it to make it readable. It seems fairly typical of small, sealed relays. A fact that pops out quite clearly is that the mechanical life of the relay is far greater than the life of the electrical contacts. The mechanical lifetime is so long, even when switched continuously at a rate of over once per second, that it is effectively eternal in typical ham use.

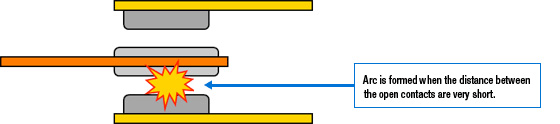

The shorter electrical lifetime spec is misleading since it is for the rated contact voltage and current. When these are lower the lifetime increases. The chart at right is also from Omron. Clearly there is a benefit from choosing relays with higher ratings than what will be experienced. Better yet, by avoiding hot switching the lifetime can be greatly extended.

By avoiding hot switching and using high current contacts the lifetime is sufficiently extended that there should be little concern for the reliability and durability of the relays in my home brew projects and the commercial products I use. Relay lifetime can easily exceed my lifetime.

Hot switching can be avoided or mitigated in well designed equipment. Measures include:

- Software features to prevent hot switching of antennas. I have this feature partly implemented in my home brew station automation system.

- Sequencing of circuits so that relay closure occurs before current is applied, and the relay opens only after the current is cut. Sequencing of the input and output port relays is standard for the ports of high power amplifiers and in V/UHF systems with mast mount LNA (low noise amplifiers).

- Step-start relay coil with a higher than nominal voltage so that closure is rapid. Arcing and contact wear are thus reduced when hot switching high voltage or current is unavoidable.

- Sequencing or ramping motors and other devices with a high initial current. In our shacks the most common application is high power motors in rotators such as prop pitch motors.

By avoiding hot switching entirely you can achieve relay lifetimes of well over 1,000,000 on-off cycles. The TE application note I linked to has a lot more on the topic worth reading, including contact materials, arc mitigation and other recommendation for selecting relays.

An amusing story a friend told me related to the fourth bullet above was using relays to switch a prop pitch motor. Depending on cable resistance, the motor starting current can be 20 A. One day the contacts fused from excess arcing and he didn't immediately notice that the motor hadn't stopped. Luckily the damage limited to a shredded coax rotation loop.

Now he sequences the power by first energizing the high current DC relay and then the low current AC mains of the 24 VDC power supply. I plan to do the same with my prop pitch motor; currently, I do the sequencing with manual switches.

If you must switch transmit level RF and proper sequencing cannot be guaranteed, or the RF voltage is high, there is the option of vacuum relays. They are expensive, new or used. They can be found on many amplifiers. They are also useful when switches are needed at high impedance (high voltage) points of an antenna. The contacts can still be damaged by excess arcing but they should not oxidize.

The photo at right shows the effect of arcing on relay contacts. This relay has failed, will fail soon or the contacts might even fuse with continued abuse.

The relay contact protection measures described above are fine for high power switching but not necessarily for small signal switching. You might think that small signal switching is not worth worrying about, but it is. This is as true for relays used in receive arrays and control systems as it is for RF relays that must work well for both transmit and receive.

Contacts oxidize or undergo chemical changes due to current flow and micro-arcs. Open relays will accumulate grime. Sealed relays, like most of those I use (see above), are largely immune to the latter. There are mitigation measures described in the linked TE application note. However, placing components across the contacts that are suitable for DC and 60 Hz AC, it is not appropriate for RF applications.

The easiest way to deal with contact problems in sealed relays is to periodically switch them under load. In this case arcs are our friends. They burn off unwanted oxidation and other unwanted chemicals and restore low resistance conductivity. There is micro-arcing even for the small DC currents switched by the relays in my automation system.

Antenna relays that are usually not hot switched can be periodically switched while transmitting to clean the contacts. Typical power levels commonly quoted to do this range from 20 to 50 watts. Cycling 10 under load may be sufficient. Don't try this with your big amplifier! Those arcs can rapidly damage the contacts. In any case, amplifiers with fault protection will quickly go offline when an arc occurs.

I occasionally did this when I had I was manually switching antennas, modes and directions and I suspected a problem. It didn't hurt to do it even when the problem might be elsewhere. In my case it always turned out to be a relay in the transceiver or amplifier. I can't do this with the automation system since it doesn't allow hot switching. Instead I would have to add a "cleaning" feature or temporarily connect the control cables to the manual antenna controller, which I keep as a backup. But I have yet to bother since there have been no recent relay problems to resolve.

Returning to the matter of relays used solely for receiving systems where the RF level is always small, dynamic cleaning methods don't work well since there is no arcing. If the contacts corrode there may be little remedy except replacement. Contact design and coating are particularly important. For example, using multi-pole relays in parallel for contact redundancy. Gold plated contacts are another possibility.

An increase of contact resistance can weaken reception, especially at the low impedance 50 Ω side of the receive antenna switching circuit. Contact resistance will likely get worse over time unless the contacts can be cleaned. Sealed relays protect against environmental effects but also make it impossible to access the contacts to burnish them. I have had relay contact problems in my rebuilt Beverage head ends. Cycling the relays has served to reserve intermittent problems until now. It wouldn't surprise me if I eventually have to replace the reed relays in the remote Beverage switch (see below).

A trickle DC current can serve to wet the contacts to keep relay contacts clean in lieu of arcing. Receive RF is far too weak on its own for contact wetting. Combined DC and RF is most commonly found in bias-T circuits where the coax carries both, with signals combined on one end and separated on the other. This is done to eliminate a separate control cable run to the relays at the antenna end of the coax.

The only place in my station that I use a bias-T this is to reverse direction of my three reversible Beverages. There is a separate control cable to the remote Beverage switch, with one line putting +12 VDC onto the coax to the active Beverage via a bias-T circuit. The DPDT reed relays in the remote antenna switch thus carry both DC and small signal RF to the bias-T in the Beverage head end.

Does the reversing current help keep the reed relay contacts clean? I don't know. I've never had a problem with the contacts except when lightning struck the Beverage system last year. Those contact arcs destroyed the relays.

Contact wetting is in conflict with a bit of ham lore. There is a common belief that a DC bias on relay contacts can worsen contact resistance over time. Certainly I've seen contacts develop problems over years of use but I doubt whether that is the reason since it runs counter to my understanding. I don't know the truth of the matter so I thought to mention it since may encounter it from time to time. There could be a galvanic effect but it may be nothing more than a lack of arcing to clean the contacts.

Wrap up

Solid state switching has its own challenges despite not have moving parts and physical contacts. When employed correctly, relays will last a lifetime. There are inexpensive relay boards for Arduino, Raspberry Pi and similar controller that save the trouble of designing and building solid state control circuits. For switching high power RF, relays remain the easiest and most cost effective solution. That could change in coming years

In summary, relays are great. It's a matter of choosing suitable devices and following best practices to keep them healthy. They're inexpensive enough that replacing them isn't a great burden.

My relay phobia is unjustified.

No comments:

Post a Comment

All comments are moderated, and should appear within one day of submission.