The title is not really serious: there is no such thing as surface rust. Rust is rust. It starts at the surface and then penetrates deeper. There is a quip that says surface rust is a term usually only heard when someone is trying to sell you a tower.

The question to ask is: how bad is the rust? Over the decades I have come to almost always dismiss a used tower that has "a little surface rust" or that "just needs a coat of paint." Buyer beware! You may not want to overlook a bargain but know the danger signs. In particular, beware of used towers exposed to saltwater since rusting is accelerated and it is more likely the tower is unsafe. A fresh coat of paint can hide many defects.

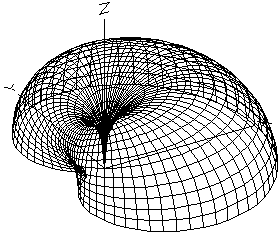

There is another saying: rust never sleeps. This one is true. Rust never goes away on its own; you must deal with it. If you don't, you end up with a tower that looks like this:

This article is about tower rust, judging the severity and dealing with it.

Hopefully your tower will never suffer rust like that pictured above! It is a Trylon tower section leg that I replaced with a new one. The previous owner stored the tower for years on the ground -- which you should never do -- allowing moisture to erode the hot-dip galvanized coating and then aggressively attack the base metal. Tower sections stored outside must be kept off the ground with lumber, bricks or another sturdy support.

In this case the price was right so I took it and repaired the damage by removing the rust and replacing parts that were beyond repair. The manufacturer advised me against doing the repair, which was very understandable. Confident about the extent of the damage and my ability to deal with it, I acquired the parts and went to work. The tower has been standing for almost 5 years and has largely been trouble free, despite supporting large antennas and all the wind and ice to be expected in this climate.

Above is a less severe case; I've seen far worse in ham installations. The tower is several decades old and has been painted a couple of times after the original galvanizing eroded and rust appeared. How bad is it? There are several increasingly aggressive methods of rust removal to guide us:

- Rust that can be wiped off or comes off with several strokes of sandpaper, steel wool or similar abrasive pad

- Rust that requires a wire brush or moderate use of a rotary power tool, before sanding

- Rust that will only come off with a file or grinder

In all these cases it is possible to achieve a flat, smooth and rust free surface ready for painting. However, other than for the first in the list you need to think carefully about the consequences. Rust is steel that has been chemically altered and removed from the base metal, which unavoidably weakens the structure.

That weakening has nothing whatsoever to do with removal of the rust. We remove the rust to, first, inspect and assess the remaining metal and, second, to prepare the surface for a protective coating to prevent further rusting. More advanced rusting with fissures and pitting requires removal of good steel to achieve a clean surface.

In most cases a judgment call is required, and that is not easy to perform. Engineers and tower manufacturers will press for replacement over repair for ultimate safety. This is sensible and not a ploy to separate you from your money. It is difficult to impossible to certify a rust damaged tower.

To put it another way, without a detailed engineering model you don't know the impact of removing deep rust damage. When you've ground down to base metal and you measure the thickness of the remaining metal with precision calipers, what will you do with the data? This is especially critical with narrow gauge steel where removing 0.75 mm (~1/32") of a 1.6 mm thick (#16 galvanized) brace leaves only 50% of the original. The same rust depth in ¼" steel plate is rarely a concern.

My one inviolate rule is to never purchase a used tower that has been painted due to rusting. The paint makes it very difficult to assess the tower. I have to see the metal to have any hope of judging its quality. I can paint it afterward, if necessary.

Quite a lot of the rust on the above tower falls into the third category. That's a problem for those narrow gauge braces. It's not my tower, so all I did was pass along my assessment.

Compare that to the rust inside the Trylon leg, at right. This is an area that was cleaned of rust and coated with cold galvanizing paint before the tower was raised. Some of the rust has returned. It came off with a few swipes of sandpaper, ready for painting. This is not rust that imperils the tower.

Rust maintenance on the Trylon

Towers with tubular legs worry me. There is no good way to inspect the inside for rust damage. Sealing the top of the legs isn't helpful since weather-induced condensation will coat the inside walls with water and the interior humidity will be high. For those opting for towers with tubular members it is strongly recommended to buy the very best.

In the US, Rohn is a good example whose tubular leg towers are popular with hams. They have an admirable service record. But, do not bury the bottom section since the condensed water inside the liegs will collect at the bottom and eat the steel from below. Use a proper concrete base to avoid water pooling and the invisible corrosion it promotes.

Trylon Titan towers are made from formed sheet steel members that are heat treated, hot dip galvanized and bolted together. They are reliable self-supporting towers for medium size HF yagis -- but, please check and follow the specs. They are in wide use by Canadian hams. For the purpose of this discussion, there are no hidden spots for rust to hide. If it's there, you will be able to see it.

Nothing is forever and so it is with rust removal and paint. After being up for more than 4 years there is rust on a few of the repaired areas. This was to be expected, and now it has to be redone before it becomes more than "surface" rust. I had to climb the tower in any case to reposition the mast after a windstorm overpowered the rotator mast clamp, again (hmm, maybe that's a topic for a future article).

Before pushing on, it is worthwhile to discuss rust that does not require treatment. Above is the Hy-Gain Tailtwister rotator on a Trylon tower shelf (in shadow at upper left). The steel shelf is not rusted. It is due to rust being washed by rain and snow from further up, pooling on the horizontal surface and the rust residue remaining after the water evaporates. Typical rust sources are steel masts and non-stainless fasteners.

At right you can see the beginning of rust at a spare hole in a tower leg and on the left edge of the leg. Galvanizing and paint often don't adhere well or form a thinner coat at edges and corners. Often it is better to leave it be since removing the rust and painting may make it less durable than its current condition.

My recommendation is to not touch it until the rust is more prominent and begins to spread onto the flat surfaces of the leg. Loss of steel from rust in these places does not weaken the tower. My complacency ends when I rust repair reduces the thickness of the tower member.

Like an experienced woodsman I blaze a trail while inspecting the tower for rust. As I go up the tower I place markers where rust is found. You don't have to do this if you repair each spot as you locate it. I find that marking first and repairing later is a a more reliable approach since, if you do it on the same climb you will get tired and sloppy, or the weather will change and you have to continue another day, and you will forget where you stopped.

A marker is as simple as a bit of electrical tape. It's cheap and reasonably visible, and you almost certainly have a roll of it handy. Use a colour other than black for improved visibility. Take care to place the tape near the rust patch and not on it.Finding all the rust can be difficult. Towers have vertical, horizontal and diagonal members, and insides and outsides. For maximum coverage I climb the tower on one face and down another. I look up, down, inside and outside every few feet. I clip on for a closer inspection and to mark the spot. It can be tedious work, so stay alert to minimize the chance of missing rust.

On the next climb I clean the rust on the way up and paint the bare metal on the way down. It is very important to paint on the way down, which should be obvious if you think about it for a moment! All the tools I need are a few scraps of sandpaper and a rag to clean the dust. When it comes time to paint, look closely to ensure you can see all the sanded areas. Galvanizing and bare steel can look remarkably alike and it's easy to miss spots. Missed spots will soon have a new coat of rust.

It is safer and easier to use spray paint on the tower. Calm days above ground are rare so wear old clothes and stay upwind if you can. Don't fret over paint that blows away; paint isn't expensive. I doubt that more than half the paint I use hits the tower even in a light breeze. Return a day or two later to apply a second coat.

I hesitate to make a product recommendation since the VOC (volatile organic compounds) and zinc content varies with local environmental and safety regulations, even for the same brand. In Canada, retail cold galvanizing paint has lower VOC and zinc content than what professionals can access. I use a retail product by Rustoleum and it has worked pretty well for me. Talk to a tower pro who can direct you to the best locally available product.

One caution about paint is to be careful that it is the right type for the job. Above you see the rust protection paint on one of my guyed towers has worn off by repeated abrasion from my boots. The original is very good and adheres to the galvanizing below. It can be difficult to find a paint that adheres well to older paint, and to properly prepare the surface. It can be an extraordinary amount of work.

Where the original paint is gone, a galvanizing primer is usually needed before the top coats are applied. Surface preparation includes removal of curled and bubbling paint. This is important since these create voids where water can pool and promote rusting. Failure to prepare the surface can make the problem worse because the old paint is stiffened and thickened so that it will last longer and more effectively trap water than if left alone.

Aside from rust repair, I have a few more tower maintenance tasks to complete this summer. Once those are out of the way and the hay is harvested the antenna work can begin.