One windy morning in early December I was out in the bush doing Beverage antenna maintenance. As I stepped back out into the hay field I happened to look up. I saw that something wasn't right. The upper yagis of the 15 and 20 meter stacks were not pointed where I had last pointed them. As I continued to watch the yagis slowly spun in the wind. The mast was turning freely. That's bad, very bad.

Despite the cold and windy weather I suited up an hour later and climbed the tower. I considered it an emergency because freely spinning yagis can do a lot of damage to the cables. Coax isn't expensive but the repairs would be lengthy and very uncomfortable due to the cold weather.

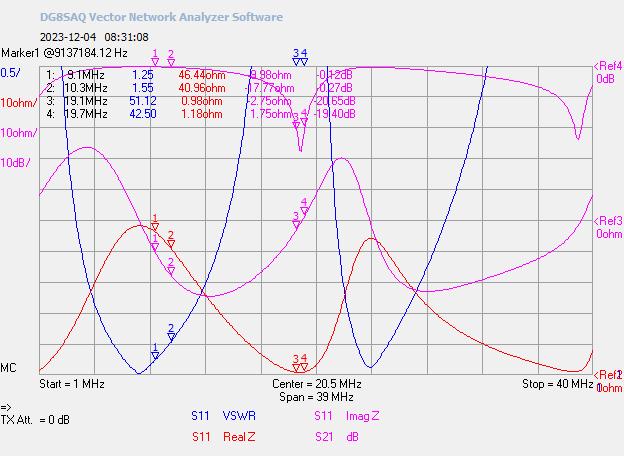

Without stopping to discover the cause, I installed the mast grip previously stashed at the top of the tower and secured it to a tower leg. That stopped the mast from turning.I inspected the coax rotation loops and I lucky to discover that I had caught the failure before damage was done. Later, from the shack, I confirmed that the impedance of both yagis was nominal.

After dealing with the emergency, I dropped a few feet to inspect the mechanical coupling between the prop pitch motor and the mast. The trouble was easy to spot. The 5/16" × 3-½" bolt that couples the prop pitch motor drive shaft to the 2-7/8" short coupling pipe had snapped.

The original was a grade 8 bolt. After an earlier repair I carelessly substituted a grade 5 bolt. Shear forces snapped the head off the bolt. The headless bolt subsequently squirmed its way outward until the pipes were fully decoupled.

Rather than repeat myself, interested readers can refer to earlier articles with the description of the system and how I later improved it to prevent water damage to the upside down prop pitch motor. On a positive note, on this trip up the tower there was no sign of water getting into the motor or the return of motor trouble.

Returning to my emergency climb up the tower, my hands were going numb from the fierce wind chill. The mast now secure, I raced to the ground before I could develop hypothermia. The speed at which I worked meant that I had to leave the yagis pointing south, which is not a terribly useful direction for me. That's where the wind wanted them and I was in no condition to fight the frigid wind. The important thing was that I averted a worse outcome.

A few days later the weather became unseasonably warm. I spent 3 hours on the tower that day to jack up the mast, disassemble the rest of the drive system and park the yagis northeast. I neglected to take a picture at the time so I took the accompanying picture after the full job was done after Christmas. Here you can see the improvised jack at rest. The weight of the mast and antennas is once again supported by the lower bearing, 5' below the mid-mast bearing plate seen here.

You can probably discern from the arrangement of the bolts how the jack functions. I used what I had available at the time, and I can't really recommend doing it this way. It was an improvisation when time was of the essence. The jack is only stable if the mast can't turn.

I tossed the parts of the motor drive and mast coupler onto the workbench for when I would have time to inspect them. I had to decide whether to repair or replace the system. It couldn't be done quickly since the cold weather had returned and the holidays were approaching.

I had long intended to redo the drive system because the design is awkward for maintenance and there is play in the system that allows the yagis to rock back and forth more than I'd like. Good intentions aren't good enough when I kept putting it off in favour of so many other items on my project list. This emergency moved it to the top of the list.

One thing regular readers will know is that I do not hide my mistakes. The design and its implementation are flawed. They are flaws that I believed would not cause problems or at least cause them far enough down the road that there would be ample time to plan and implement improvements. There was plenty of time, but I spent it elsewhere. It is easy to let things slip when they seem to work and so much else is waiting to be done. Let's take a closer look at the problems I uncovered.

I took the time to illustrate the design since it is critical to understanding it and its failings. I included a side view and a bottom view. I didn't have a blank sheet when I came up with the design since there were several constraints I had to accommodate:

- The motor crown gear was welded to a 1-¼" steel pipe with an OD of 1.66".

- A bearing had to take the weight of the mast and antennas since a prop pitch motor can't deal with that.

- The 20' mast falls ~2' short of the bearing plate. It had to be extended to reach the bearing.

- The available tower girts for bearing and motor plates resulted in a tight fit for the drive shaft between the motor and the bottom bearing.

Please note that the diagrams are not complete. I left out the many washers (flat and lock), where the pipes are tapped, and several other details.

I chose a 3.5" OD aluminum pipe from my stock of materials as the mast coupler. Two cross bolts (purple) connect them. There are 14 gauge (0.078") steel spacers to fill the gap between the coupler's 3.068" ID and 2.875" mast. Some play is acceptable but not too much.

The weight of the mast and antennas rests on the bottom 75 mm fully sealed industrial bearing that is designed for both axial and radial loads. A 2.875" aluminum (6061-T6) schedule 80 pipe serves as a drive coupler. It fits through the bearing bore and has one cross bolt to the mast coupler, and four 0.078" steel spacers. A short length of the drive coupler projects below the bearing plate. There is one cross bolt to connect the pipes.

There is a large 0.33" gap between the drive shaft and the drive coupler. ⅜" nuts fill the gap, but not perfectly. They are difficult to install so a gap needed to be left. Two positioning bolts help to prevent movement of the drive shaft.

It worked for several years despite its flaws. There is too much play in the drive coupler due to the lack of spacers at the bottom of the mast coupler. The adjacent picture shows one of the dual spacers fitted to the top of the drive coupler. That and the use of only one cross bolt allowed the bottom of the drive coupler to sway side to side under torque. The creaking could sometimes be heard on the ground.

The bearing bore is ~2 mm wider than the 2.875" coupler. I didn't worry about it too much at the time because the crown gear on the motor can accommodate the play without binding.

However the most serious problem was the cross bolt to the drive shaft. There is a high shear stress on the bolt and pipe openings due to large gap between the pipes (red circles). The stress cycling is continuous due to the antennas rocking in the wind and when the mast is turned. That is why I selected a grade 8 bolt. In the earlier picture you can see the marks on that bolt, and on the grade 5 bolt that failed, where it passed through the pipes. There is less bending stress (orange circles) between the mast and drive coupler to the 3.5" mast coupler since the gap between them is small.

I could have had a larger pipe welded to the crown gear. I didn't because the tight fit between the motor and bearing plates required fitting the drive shaft at an angle through the tower face. While that may have been a mistake there was no opportunity at the time to design a better system. At least I couldn't come up with one that satisfied all of the previously listed constraints.

Another measure I could have taken was to install more cross bolts to reduce play. I tried to keep those to a minimum because I was concerned that more holes would increase the risk of stress cracks in the pipes. That may have been a mistake since the total load isn't higher and more bolts helps to distribute the load, thus lowering point stresses. Also, when the pipes twist out of alignment under load there are greater bending stresses on the pipes and bolts.

The big design questions must be left for the future. There was an immediate problem to be solved or I'd spend the first half of 2024 unable to rotate the upper 15 and 20 meter yagis. I inspected the components to determine whether they could be reused and what could be improved without full replacement.

Once I decided on a course of action I reascended the tower on a unseasonably warm Christmas day to retrieve the mast coupler. I had left it there as insurance 2 weeks earlier in case the jack failed. I adjusted the jack and pulled the bearing plate so that the coupler could be slid off the mast.

I was surprised that the aluminum (6061-T6) components were in good shape. The holes for the cross bolts were at most only slightly elongated by the repeated torque stress. Perhaps that was due to the thick walls and relatively large bolt diameters that distributed the stress over large surfaces. There was noticable elongation of the 5/16" holes in the steel drive shaft. There were also wear marks at the bottom of the mast coupler where movement abraded the aluminum. It was superficial so it, too, could be reused.

I gave myself one day to rebuild and reinstall the system, in the interests of safety (I trusted the mast jack only so far) and to exploit the record breaking temperatures. It may have been a strange way to spend the holiday but you do what you have to do. I kept a couple of friends on standby in case I needed to interrupt their holiday to help with the tower work. Luckily there was no need to inconvenience them. I appreciated their willingness to come to my assistance if needed.

All the work was done in my basement workshop since my garage workshop isn't heated and I had more lighting available for evening work. The picture doesn't show the full setup and procedure where I used levels and other tools to ensure good alignment of the new holes. I didn't work blindly with a hand drill!

I made several improvements to the drive shaft and its coupler:

- I widened the holes in both to accommodate a ⅜" grade 8 bolt as a coupling pin. I judged that the wider hole left more than enough material to avoid stress cracks. The widening conveniently removed the elongation of the drive shaft holes. The bolt is ½" longer than the one replaced so that the unthreaded shank is in contact with all 4 holes. For applications with shear stress you should avoid having bolt threads in contact with the pipes where the bolt diameter is thinner and therefore weaker. The threads also abrade the pipe.

- Two more holes were drilled and tapped so that there are 4 positioning bolts. They stabilize the drive shaft within the coupler without the need for difficult to install spacers on the cross bolt.

- The positioning bolts are now grade 8. I found that their use as set screws on a constantly wiggling drive shaft rounded the tips of the grade 5 bolt threads. They were difficult to remove and afterwards I had to chase the threads in the coupler.

I next turned my attention to the mast coupler. A second cross bolt was added. To avoid placing it too close to the bottom end, the second bolt is ⅜" rather than ½". Since there was no elongation of the original holes I saw no need to make the new cross bolt any larger. Both bolts are grade 5.

New spacers were shaped for the top of the drive coupler. I added a ring spacer below the cross bolts using the same 14 gauge steel. The ring spacer is visible in the picture on the right.

There is significantly less play with this arrangement. A better solution would be to make the mast coupler from schedule 80 pipe where the ID is 2.9". That would leave a gap of 0.0125" between the couplers and eliminate the need for spacers. There was no time for that to be done.

The picture above shows the assembly from the bottom of the drive coupler. All the bolts are there, including the cross bolts through the mast coupler just visible through the pipe. A carabiner is already attached for lifting.

In addition to the enlarged holes, the water cap on the drive shaft had to be replaced. The glue on the aluminum disk seal didn't survive the trip to the ground. I cut a new one from the top of a food tin, glued and taped it to the pipe, and added caulking to prevent the tape from peeling.

Here you see the prop pitch motor attached with the new coupler system installed. There is almost zero play. For this design the difficult part of the installation is to wiggle the mast back and forth to align the pipes and drive the cross bolt through the 4 pipe holes. Luckily the wind was calm that day as I used a long wrench to rotate the mast back and forth until the bolt was driven home.

At right is the view looking down on the mast coupler and bearing. The only visible difference from the original is the added cross bolt a short distance above the bearing.

Since I didn't have an assistant, the final test had to wait until I climbed down (with a cumbersome load of steel). Back in the shack I confirmed that the rotator was working again.

I would like to do another test with a friend operating the controller while I monitor the rotating couplers on the tower. That will have to wait for a warm winter day after the holidays are over.

In the spring I'll discuss the design with a machinist and see if we can come up with a better system. As already said, it must be easy to install, remove and service. It must also not involve jacking the mast a large distance or the removal of the prop pitch motor. There are several possibilities brewing in my mind so we'll see where this goes.

I am relieved to enter 2024 with a fully functioning rotation system for the 15 and 20 meter stacked yagis. There are months of contests and DXpeditions coming up before spring arrives. I can live without being able to rotate the yagis for a while during the summer lull, and that may be my best opportunity to address the system design.

Although having a big station can be a lot of fun it is also a lot of work. Things break and maintenance is an unending job. The failure described in this article may be worse than most, but there are many smaller issues that regularly crop up. Despite few readers having towers and antennas of this size, my hope is that my description of the design, design flaws and the repair will prove to be helpful.

This is my final article for 2023. I wish all of you a happy new year.