Not long ago I described a

single-band stack switch utilizing an L-network to transform the 25 Ω parallel impedance of two yagis to 50 Ω. The network is bypassed when one of the yagis in the stack is selected. L-networks have advantages over the more traditional transmission line transformer on a ferrite toroid:

- High efficiency

- Ease of construction

- Low cost

- Small physical size Since it doubles as a filter it helps reduces inter-station interferenceNetwork can be dynamically altered to suit 3 or more yagis in the stack

However it is not without its disadvantages and challenges:

- It is too narrow band to be used on more than one band

- Coils and capacitors must be chosen and properly used to achieve the desired efficiency, stability and power handling

- The network must be tuned (L and C) for the stack parallel impedance and frequency range

In other respects the stack switch design is quite similar for both broadband transformers and L-networks. I'll reproduce the generic schematic of the two antenna stack switch here from an earlier article for your convenience.

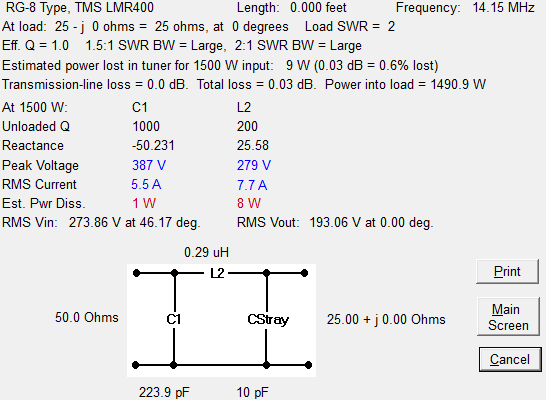

There are many software applications for designing L-networks. I use TLW that comes with the ARRL Antenna Book. It is very simple to design the "tuner" to match the 25 Ω parallel stack impedance.

I chose a low pass network because the coil is small and the capacitance easy attainable with parts on hand. It will modestly reject 10 meter band energy which may be helpful during a contest.

I left the coil Q at the default 200 even though a higher Q coil is easily attainable. Indeed I measured a Q of 330 on a VNA for the L-network coil (made of #12 wire). The reason for assuming a lower Q is that in a tightly packed enclosure it will inevitably degrade and I want to be conservative about the design. Recall that Q = X / R so a lower Q means greater power dissipation due to the ESR (equivalent series resistance).

Doubling the Q to 400 halves the dissipation from 6 to 3 watts at 1000 watts. However, average power dissipation is typically 50% less for CW and SSB, and another 50% less accounting for receive and transmit cycles. In theory the network will not get hot, and in practice? That requires measurement, which I will come to later.

Construction

I went for the smallest aluminum enclosure that would fit, was durable and had few seams. It's a Hammond cast aluminum enclosure approximately 4.5" × 3" × 2" (1590T). I drew the layout on paper and measured it, including the height and especially with room for the coil to stand free.

When the parts and enclosures arrived I laid the parts inside the enclosure, made a few measurements and started punching holes. First to go in were the UHF jacks. A few of the 12 screws support spacers for the L-network above the connectors and relays. K3 and K4 were attached first, using heavy wire from the connectors as mechanical support.

All the relays are held in place by the wiring. A PCB is better for reducing stray capacitance and inductance and for reducing impedance "bumps" along the signal path wiring. For short wires and HF sloppiness does not cause serious problems so I went for the simplest construction method. I've

done it before and it can work well despite the ugliness.

A spacer lifts the terminal strip and coil to mid-height. Strips of aluminum were cut and drilled to hold the 230 pf capacitor (100 + 100 + 30), with a spacer lifting them to the same height as the coil. The coil, capacitors, relays and wires are designed or selected to carry high power. The cold side of the capacitor assembly is adjacent to the enclosure walls so it is not at risk of shorting.

A terminal strip rather than a connector is used for the control cable. While less elegant I find this method easier to work with. When something goes wrong it is easy to repair on the tower without bringing it down to the ground. From left to right the connections are upper, lower, both and DC ground. Since both (BIP) is the default only 3 control wires are needed.

The terminal strip supports the 1N4001 diodes for the switching matrix and relay coil back EMF protection, and capacitors (not attached in the photo) for bypass to prevent RF rectification by the diodes. The small hole on bottom left is for the control cable. Holes to weep moisture and to mount the tower bracket will be added later.

Adjustment and testing

A friend loaned me his

VNWA3 for a different project. Since I had it I used it to test and adjust the stack switch. This is a very nice VNA that I like so much I went ahead and ordered one for myself. It was used to measure coil Q, adjust the L-network and to measure SWR and insertion loss. In the photo below it is configured to measure insertion loss, which requires a two port VNA. One yagi port has a 50 Ω load attached to ensure equal power division.

The coil turned out to have too much inductance so that the L-network centre was ~12 MHz. The stray inductance was larger than expected. On closer inspection the mounting of K1 and K2 on either side of the input port had interconnecting wires passing alongside the coil which, via the relays, seems to behave as an additional coil turn. As we'll see other than the stray inductance performance is still very good.

I cut a turn off the coil and tried again. This time its centre was 13.3 MHz. There was no need to remove and measure the inductance since a accurate calculation can be done based on its dimensions. The original inductance of 0.31 μH was reduced to about 0.2 μH. The stray inductance isn't much and wouldn't be an issue on, say, 80 meters, but as we go higher in frequency the stray inductance contribution to the total is significant.

I'll have to be more careful about the layout for the 15 meter stack switch and, eventually, the one for 10 meters. An alternative is to use a high pass L-network which requires a higher (shunt) inductance. On those two bands a high pass L-network would also be more useful to reduce inter-station interference.

With the cover in place the centre frequency rose from 13.3 to 13.8 MHz. Inductance is reduced for a coil near an aluminum sheet because the non-ferrous conductor "cuts" the field lines. I couldn't predict beforehand how great the effect would be. A toroidal shaped coil reduces the influence of the enclosure but this is difficult to shape without a form and a form would increase dissipation by dielectric heating.

Trial and error compressing and spreading of the coil turns raised the centre frequency to the low end of the band. Going further would require adjustng the shunt capacitor (not easy!) and since it performs well across the band I left it as is.

Above is the VNA sweep of the input impedance and insertion loss. SWR is excellent across the band. Of course each port should ideally be -3.00 db since the power is being split between two 50 Ω loads in parallel. The additional -0.05 db is the insertion loss. It ranged as high as -0.07 db depending on port and load quality. The theoretical -0.03 db insertion loss calculated by TLW is difficult to achieve in a real device.

A -0.05 db insertion loss translates to a dissipation of 11.5 watts with 1000 watts of transmitter power. It is 16 watts for -0.07 db loss. This is very reasonable and better than a transformer.

Bypassing the L-network (selecting upper or lower yagi) unsurprisingly improves performance. Insertion loss is 0 db, which indicates that the wiring and relays are very low resistance. The SWR into the switch is 1.02 with a calibration quality 50 Ω load but a little higher when terminating to the VNA for the insertion loss measurement. That is, the S21 path is not quite the same as the through calibration done with a different cable arrangement.

Smoke test

The final test is to determine the true insertion loss by putting power through the stack switch. Since a 1% power drop is very difficult to measure with power meters I went with the finger test. This involves putting power through the stack switch for a while then opening it and touching the components to see how warm they are.

Two 20 meter antennas were used for the smoke test since I don't have two 500 watt dummy loads. I picked a frequency where the SWR on the high TH7 and low TH6 were low and close. I moved the coax from the two operating positions to the stack switch, selected the antennas on both sides of 2 8 switch and plugged the amplifier into the input port of the stack switch. A 9 volt battery and a toggle switch selected upper, lower or both in phase (BIP). Don't touch the selector when transmitting!

For the first test I transmitted a 100 watt carrier for 1 minute. I picked a time when 20 meters was dead to avoid any possibility of bothering others -- at this point in the solar cycle the test was easy to schedule! The coil was barely above room temperature after the test so I turned on the amplifier.

The

Drake L7 does not have a heavy duty power supply so I have little difficulty staying within range of the Canadian legal limit with a pair of 3-500Z tubes. For this test I am transmitting as much as I can get out of the amp, which you may be able to see in the photo. Note that the picture was taken with the stack switch cover off but it was on for the actual tests.

I increased the power in steps to minimize the risk of mishaps. I tested the temperature of the stack switch components after each test. Finally I transmitted full power for 30 seconds (this amp isn't capable of continuous duty operation). The coil was warm to the touch but not at all hot. The transmit doorknob capacitors stayed perfectly cool,

as was expected.

No smoke was emitted so the smoke test was successful. And please be careful trying this: you don't want the transmitter accidentally keyed while your fingers are inside the stack switch.

Parallel impedance

The efficiency and input SWR of any network or filter is dependent on the impedance presented on the other port(s). This stack switch is no different, whether it uses an LC circuit or a broadband transformer. Deviate from the nominal 50 Ω and its behaviour will be different. The question is how different.

Yagis stacked in the conventional fashion use in-phase parallel impedances. The calculation is straight-forward though not trivial. A calculator for impedances is useful. There are many online (

this one for example, as shown below) and they can be implemented in a spreadsheet.

Play with them for a while and you'll discover that yagis with equal impedances and low SWR work best. Similar results can be had when the X values are opposite and equal or when the R values are geometrically opposite of 50 Ω, if the deviations are not large.

For the smoke test the measured yagi impedances are 39 + j9 and 44 + j2, with respective SWR of 1.38 and 1.15. The parallel impedance is 21 + j3, with an SWR of 1.25 relative to 25 Ω. The measured SWR at the input port of the stack switch is around 1.2 to 1.25, indicating that the 2:1 transformation ratio remains valid for these modest impedance deviations. That's good.

Although in this case the SWR was between that of the individual yagis that is usually not be the case when the SWR is high. Further, the network will not have a perfect 2:1 transformation ratio and insertion loss will rise for large deviations from the nominal 50 Ω impedance.. By how much depends on the network design and the impedances.

Many hams don't realize that the broadband ferrite core transformer in commercial stack switches exhibits similar misbehaviour with deviant impedances. From talking to other hams it seems to be a common belief that transformers are better than LC networks. I don't understand why this is.

No matter the network you are well advised to stack yagis with matched impedance curves (ideally electrically identical antennas) with a low SWR across the band. That will also ensure equal power division which is required to realize the full gain potential of a stack.

For high Q antennas such as tri-band yagis take care that the impedance transformation network can handle the higher power dissipation and voltages at the band edges. The higher the power you run the more critical this becomes. The risk is greater for high duty cycle digital modes.

Future installation

Stack switches are pretty straight-forward devices. They contain no black magic, just a simple matching network and relays. Any ham can build one, even me!

It is unlikely that this stack switch will be put to use before mid-September. The upper 20 meter yagi is still on the ground, there are no phasing lines on the tower, routing of the control cable remains to be done and the rotator is in the workshop. While that work is being completed I will build and test the 15 meter stack switch so that it, too, is ready to go.

Assuming all goes well the 20 and 15 meter stacks will be fully operational in October. For me that is when the season will truly begin. Since there are few rare DXpeditions in the pipeline the stacks will see their first service in the fall and winter contests. I am looking forward to it.

It is sure to malfunction, and that is unacceptable for an element of an antenna as difficult to access and repair as a 40 meter yagi. There are four of these on an element so the total number of these joints is 12 for a 3-element yagi. That's trouble with a capital "T".

It is sure to malfunction, and that is unacceptable for an element of an antenna as difficult to access and repair as a 40 meter yagi. There are four of these on an element so the total number of these joints is 12 for a 3-element yagi. That's trouble with a capital "T". With these model predictions in hand we can proceed to finalize construction of the experimental element and lift it into the air.

With these model predictions in hand we can proceed to finalize construction of the experimental element and lift it into the air. You can see in the above picture (with Alan VE3KAE steering the antenna) that the tram line anchor is the base of the 140' (40 m) tower with the 15 and 20 meter stacks. The tram is pulled tight with a winch and the antenna is manually hauled up by rope. It isn't too heavy at 52 lb (plus rigging) but it is tiring for one person. For the second session we had a larger crew to share the work.

You can see in the above picture (with Alan VE3KAE steering the antenna) that the tram line anchor is the base of the 140' (40 m) tower with the 15 and 20 meter stacks. The tram is pulled tight with a winch and the antenna is manually hauled up by rope. It isn't too heavy at 52 lb (plus rigging) but it is tiring for one person. For the second session we had a larger crew to share the work.  In total we did 6 lifts of the antenna to gather the required data. That should be enough to confidently interpolate and extrapolate the dimensions of the 3 yagi elements using EZNEC without benefit of SDC.

In total we did 6 lifts of the antenna to gather the required data. That should be enough to confidently interpolate and extrapolate the dimensions of the 3 yagi elements using EZNEC without benefit of SDC.